Sewage Treatment Plant In India

- Blog

- Albionecotech

- Sewage Treatment Plant In India

Sewage Treatment Plant in India

Table of Contents

ToggleMembrane Bio Reactor Sewage Treatment Plant (MBR)

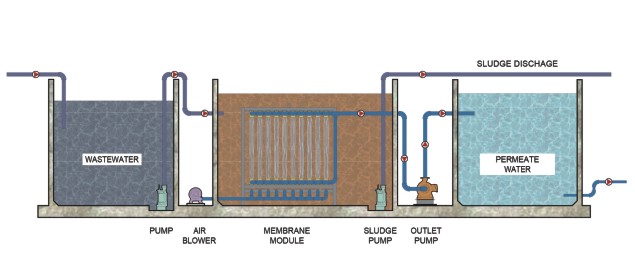

X-Flocs operates on the principle of biological/ bacterial treatment. Raw untreated wastewater is sent to the X-Flocs reactor using a pre filter screen to prevent any larger debris, plastics, etc clogging the reactor. X-Flocs module is a bioreactor fitted with a necessary air diffuser and filtration membrane with a pore size ranging from 0.1 microns to 0.06 microns.

The residence time of wastewater within the reactor is controlled by the drawing rate from the membrane module. Treated water is drawn from the reactor using the suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge.

Process

Applications

- Sewage Treatment

- Effluent Treatment

- Drinking Water

- Treatment Plants

- Compact Sewage

- Treatment Plants

- Food industries

Check out the gallery for Membrane Bio Reactor Process (MBR)

Moving Bed Bio Reactor Sewage Treatment Plant (MBBR)

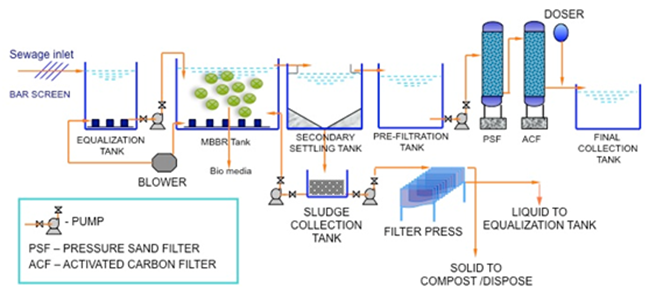

M-Flocs technology employs thousands of polyethylene bio film carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity by providing a protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells.

It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive bio film. Additionally, the bio film attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Process

Applications

- Sewage Treatment

- Effluent Treatment

- Food industries

- Nominal Parmeter Industry

Check out the gallery for Membrane Bio Reactor Process (MBR)

Sequance Batch Reactor Sewage Treatment Plant (SBR)

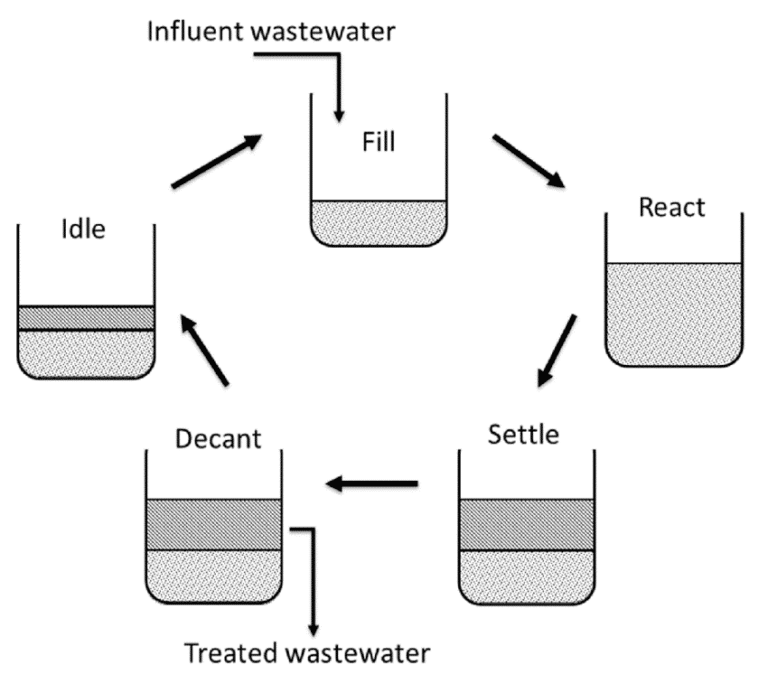

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Process

There are four steps involved when using an SBR system:

Fill cycle– There are two chambers involved in the process, with the wastewater first entering the primary treatment chamber via the inlet. This is where any solid substances will be held before being moved to the secondary chamber.

Aeration/React cycle– The second batch can now begin, with oxygen introduced into the tank via a diffuser. This is when the biological cleaning process takes place, activating the microorganisms in the waste that will start to clear away the solids.

Settle phase– Once the aeration cycle has ended, the live sludge will settle at the bottom of the tank, with the clear effluent rising to the top.

Decant phase– The purified wastewater is then fed into a discharge system via a sampling chamber and out into a drainage field or watercourse. Once completed, the sludge is then returned from the SBR tank back into the primary treatment chamber.

- Effluent with a wide range of inflow and/or organic loadings

- Effluent that requires minimal operator attention

- Effluent that requires extremely close control of effluent quality, such as for the removal of nutrients

Sewage in small to medium size communities - Effluent in industries with high BOD loadings such as food processing, dairies, and chemical plants.

Check out the gallery for Membrane Bio Reactor Process (MBR)

Water Recycling company In India

wastewater treatment companies in india

Sewage treatment plan In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant In India

Sewage Treatment Plant

X-Flocs operates on the principle of biological/ bacterial treatment. Raw untreated wastewater is sent to the X-Flocs reactor using a pre filter screen to prevent any larger debris, plastics, etc clogging the reactor. X-Flocs module is a bioreactor fitted with a necessary air diffuser and filtration membrane with a pore size ranging from 0.1 microns to 0.06 microns. The residence time of wastewater within the reactor is controlled by the drawing rate from the membrane module.

Treated water is drawn from the reactor using the suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge.

Sewage Treatment Plant

M-Flocs technology employs thousands of polyethylene bio film carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity by providing a protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells.

It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive bio film. Additionally, the bio film attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Sewage Treatment Plant

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Sewage Treatment Plant

Sewage Treatment Plant

X-Flocs operates on the principle of biological/ bacterial treatment. Raw untreated wastewater is sent to the X-Flocs reactor using a pre filter screen to prevent any larger debris, plastics, etc clogging the reactor. X-Flocs module is a bioreactor fitted with a necessary air diffuser and filtration membrane with a pore size ranging from 0.1 microns to 0.06 microns.

The residence time of wastewater within the reactor is controlled by the drawing rate from the membrane module. Treated water is drawn from the reactor using the suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge.

Sewage Treatment Plant

M-Flocs technology employs thousands of polyethylene bio film carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity by providing a protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells.

It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive bio film. Additionally, the bio film attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Sewage Treatment Plant

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Sewage Treatment Plant

Sewage Treatment Plant

X-Flocs operates on the principle of biological/ bacterial treatment. Raw untreated wastewater is sent to the X-Flocs reactor using a pre filter screen to prevent any larger debris, plastics, etc clogging the reactor. X-Flocs module is a bioreactor fitted with a necessary air diffuser and filtration membrane with a pore size ranging from 0.1 microns to 0.06 microns. The residence time of wastewater within the reactor is controlled by the drawing rate from the membrane module.

Treated water is drawn from the reactor using the suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge.

Sewage Treatment Plant

M-Flocs technology employs thousands of polyethylene bio film carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity by providing a protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells.

It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive bio film. Additionally, the bio film attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Sewage Treatment Plant

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Sewage Treatment Plant

Sewage Treatment Plant

X-Flocs operates on the principle of biological/ bacterial treatment. Raw untreated wastewater is sent to the X-Flocs reactor using a pre filter screen to prevent any larger debris, plastics, etc clogging the reactor. X-Flocs module is a bioreactor fitted with a necessary air diffuser and filtration membrane with a pore size ranging from 0.1 microns to 0.06 microns. The residence time of wastewater within the reactor is controlled by the drawing rate from the membrane module.

Treated water is drawn from the reactor using the suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge.

Sewage Treatment Plant

M-Flocs technology employs thousands of polyethylene bio film carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity by providing a protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells.

It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive bio film. Additionally, the bio film attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Sewage Treatment Plant

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Sewage Treatment Plant

website designing company in india

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Sewage Treatment Plant

Sewage Treatment Plant

X-Flocs operates on the principle of biological/ bacterial treatment. Raw untreated wastewater is sent to the X-Flocs reactor using a pre filter screen to prevent any larger debris, plastics, etc clogging the reactor. X-Flocs module is a bioreactor fitted with a necessary air diffuser and filtration membrane with a pore size ranging from 0.1 microns to 0.06 microns. The residence time of wastewater within the reactor is controlled by the drawing rate from the membrane module.

Treated water is drawn from the reactor using the suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge.

Sewage Treatment Plant

M-Flocs technology employs thousands of polyethylene bio film carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity by providing a protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells.

It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive bio film. Additionally, the bio film attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Sewage Treatment Plant

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Sewage Treatment Plant

Sewage Treatment Plant

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.

Sewage Treatment Plant

Sewage Treatment Plant

X-Flocs operates on the principle of biological/ bacterial treatment. Raw untreated wastewater is sent to the X-Flocs reactor using a pre filter screen to prevent any larger debris, plastics, etc clogging the reactor. X-Flocs module is a bioreactor fitted with a necessary air diffuser and filtration membrane with a pore size ranging from 0.1 microns to 0.06 microns. The residence time of wastewater within the reactor is controlled by the drawing rate from the membrane module.

Treated water is drawn from the reactor using the suitable pump. As the pore size of the membrane is too small to allow any bacteria or other contaminants to pass through, the treated water at the outlet of the membrane is clean with reduced organic content. This water is thereafter dosed with necessary chlorine and sent for eventual reuse or discharge.

Sewage Treatment Plant

M-Flocs technology employs thousands of polyethylene bio film carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual bio carrier increases productivity by providing a protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells.

It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive bio film. Additionally, the bio film attached to the mobile bio carriers within the system automatically responds to load fluctuations.

Sewage Treatment Plant

Sequencing Batch Reactor (SBR) is an advanced technology that uses a fill and draws-activated sludge system for wastewater treatment. It is best for treating both industrial and municipal wastes. The main difference between SBR technology and other STP technologies is that SBR uses a single batch reactor/single tank to process the equalization, aeration, and clarification compared to other technologies that use different batch reactors for various processes.