Effluent Treatment Plant

- Blog

- Albionecotech

- Effluent Treatment Plant

We are well-established manufacturers of ETP (Effluent Treatment Plant) in India. We offer a wide range of processes for removing and recycling water/wastewater, chemicals, and the recovery of precious metals. We do in-house designing manufacturing, and installation for various types of industries like Paper and Pulp, Food & Beverages, Textiles, Chemicals & Pharmaceuticals, Hotels, Automobiles, and others. We have also provided Mobile Effluent Treatment Plant as per the requirement of the customer at their construction site.

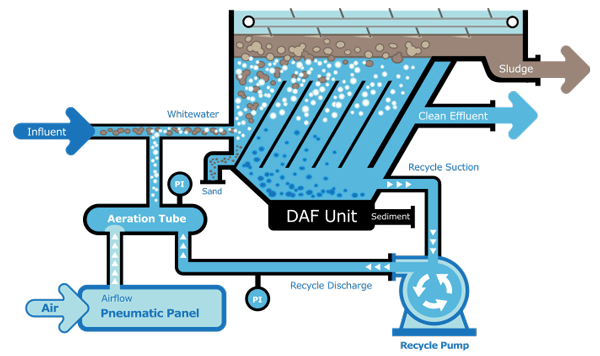

Dissolved Air Floatation System – (DAF)

Table of Contents

ToggleA-Pro is a gravity separation process whereby the separation of two phases is achieved by increasing the specific gravity difference between the two phases. This is achieved by attaching micro air bubbles, brought about by saturating water with air under pressure, and then expanding the water stream through valves to atmospheric pressure. These microbubbles nucleate into the solid particles to be separated, thus lowering the specific gravity and allowing contaminants to rise to the surface.

Process

Dissolved air flotation (A-Pro) is a water treatment process that clarifies wastewater (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

Applications

- Poultry Processing, Meat

- Processing and Packing

- Dairy Processing Unit

- Fish Processing

- Mining Industry

- Petro-Chemical Industry

- Textile Industry

- Tanneries, Other Industry

- Pulp and Paper Industry

Textile Wastewater Treatment Plant

If you work in the industrial sector, you must be concerned with wastewater management. With the rapid development of industry, an increasing number of dangerous pollutants/contaminants are released into the environment, posing substantial environmental risks, particularly water pollution, which is a major worry. The textile sector is the most water-intensive and produces the most affluent. As a result, setting up an effluent treatment plant to limit harmful wastewater discharge from the textile or garment business is required (ETP).

Textile and garment industries produce effluents with a wide range of chemical compositions, so a wastewater treatment system is essential.

Yes, an ETP, or Effluent Treatment Plant, is the finest solution for keeping the environment safe from textile waste, because it saves money and the environment while providing excellent treatment efficiency.

What is an effluent treatment plant in the textile industry?

An ETP, or Effluent Treatment Plant, is the most effective and technologically sophisticated treatment system for effluent or waste generated by diverse establishments such as industries. The various components of the ETP will be determined by the effluent’s characteristics, i.e. the type of effluent to be processed. Depending on the effluent’s quality and quantity, numerous types of ETPs are available.

The textile business generates a large volume of wastewater with a wide range of compositions and chemicals used in dyeing, printing, and other processes. Textile companies’ discharge of untreated effluent is extremely damaging to the environment, polluting adjacent water and land. An ETP, or effluent treatment plant, helps to solve this problem by safeguarding the environment from the negative effects of wastewater in the textile and garment industries.

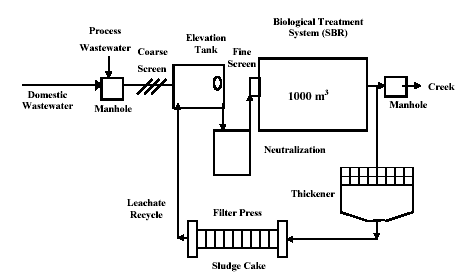

The following is a list of the treatment processes used in ETP for the textile industry:

Untreated textile effluent contains significant quantities of TSS, dyes, chemicals & auxiliaries, metal toxicants, and BOD, and must be treated before being discharged into the environment. Pollutants are removed from wastewater as it goes through the ETP, and the water quality is enhanced to an acceptable/standard level, allowing for safe ultimate discharge to the environment. Physical, chemical, and biological mechanisms are frequently used combined in ETP.

The flowchart for the above process involved is shown below

1. Preliminary treatment:

Often known as pretreatment, is a physical method of treating wastewater. It entails screening, which involves using bar screens to remove big solids such as rags, cloth, yarn, lint, twigs, and other debris that could harm the plant’s equipment. The wastewater is next exposed to the physical treatment stage.

2. Primary Treatment:

It entails physical and chemical techniques for wastewater treatment. When wastewater is pumped into the primary tank, it remains there for a long period, causing heavier particles to settle to the bottom and lighter particles to float to the top. Flocculation and coagulation are used to remove settled and floatable debris, and the water is then sent to secondary or biological treatment.

3. Secondary Treatment:

Wastewater entering the secondary tank is free of physical particles and is subjected to a biological process. Most ETPs use biological treatment to remove BOD, which includes aerated lagoons, activated sludge, trickling filters, and oxidation ponds, but the activated sludge process is the most versatile biological oxidation method used for wastewater treatment. Approximately 80% of organic waste will be eliminated here, followed by tertiary treatment.

4.Tertiary Treatment:

Physical, chemical, and biological mechanisms are used to remove remaining suspended solids, dissolved solids, and other contaminants that were not eliminated during the previous treatment steps. Several disinfection agents, such as chlorine, ozone, and UV radiation, are commonly utilized depending on the wastewater quality. After this treatment, the wastewater is ready to be disposed of or reused.

Pharmaceutical Wastewater treatment plant

Pharmaceuticals perform an important role in the treatment and prevention of disease in both humans and animals. Because they are designed to be highly active or interact with receptors in humans and animals, or to be toxic to many infectious organisms, they may have unintended consequences for animals and microorganisms in the environment. Traditional systems that use an activated sludge process are still widely used for wastewater treatment, primarily because they produce effluents that meet required quality standards (suitable for disposal or recycling) at reasonable operating and maintenance costs.

Pharmaceutical compounds are generally manufactured in batch processes, resulting in the presence of a wide range of products in wastewater generated in various operations where copious amounts of water are used for rinsing of solid cake, extraction, or equipment washing. In general, this wastewater contains:

A high organic matter content, a large portion of which is easily biodegradable (alcohol, acetone, etc).

Organic compounds that degrade slowly and refractory substances (aromatic compounds, chlorinated hydrocarbons, etc).

Compounds that inhibit and are toxic (antibiotics).

Surfactant-containing soaps and detergents.

However, it has been demonstrated that this type of treatment has a limited ability to remove pharmaceuticals from wastewater.

TWO DIFFERENT SOURCES

The presence of pharmaceutical compounds in drinkable water arises from two sources:

1. pharmaceutical industry production processes and,

2. common use of pharmaceutical compounds,

This results in their presence in urban and farm wastewaters. The wastewaters produced during various processes in the manufacture of pharmaceuticals and drugs contain a diverse range of compounds.

DIFFERENT TREATMENT TECHNIQUES

Industry requires the reuse of water after the removal of contaminants, whether pharmaceuticals or otherwise. Given the scarcity of water resources, it is critical to comprehend and develop methodologies for the treatment of pharmaceutical wastewater as part of water management.

Different treatment techniques are:

Activated sludge biological process: The most versatile and widely used biological treatment process is probably activated sludge. Even though the process is suitable for all climates, the treatment capacity will be reduced in colder environments. Activated sludge processes are typically used after primary treatment and, in some cases, followed by a final polishing step as part of a complex treatment system.

Anaerobic Digestion Process: The benefits of using anaerobic digestion are numerous, it can withstand high organic loading, produces less sludge, and has lower operating costs. Mechanical steam compression vacuum evaporators and advanced oxidation processes are other treatment options.

Moving Bed Biofilm Reactor Process: Moving Bed Biofilm Reactor processes self-maintain an optimal level of productive biofilm, the treatment is cost-effective and requires little maintenance. Unlike activated sludge systems, MBBR systems do not require sludge recycling. The use of MBBR as a retrofit increases the capacity of the existing plant.

Effluent from various sectors of active pharmaceutical ingredients (API), bulk drugs, and related pharmaceutics that use large amounts of water is analyzed, and strategies are proposed to recover the valuable compounds to a large extent, and finally, the diagnosis of very dilute but harmful wastewaters is discussed. There is no single technology capable of completely removing pharmaceuticals from wastewater. The use of conventional treatment methods in conjunction with membrane reactors and advanced posttreatment methods to create a hybrid wastewater treatment technology appears to be the best option.

Industrial Effluent Treatment Plant

It can be observed that the generation of industrial wastewater is overwhelming due to the rapid development of various industries which produce their own particular combination of pollutants are extremely contaminate the surrounding environment. Hence, environmental rules have directed all industrial units to implant effluent treatment plants to curb the direct release of untreated wastewater in water bodies.

Here, are some of the major industries which need to implant Effluent Treatment Plants (ETP) to purify the wastewater before it gets discharged are:

1. Food and processing industries

2. Pharmaceutical industry

3. Textile and Paper industries

4. Automobile industries

5. Textile and dye industry

6. Dairy and Beverage industries

How does industrial effluent pollute the environment?

The industry is a vital source of water pollution. Industrial effluent diminishes the aesthetic quality of watercourses such as ponds, lakes, rivers and etc. It causes a significant effect on human health. Moreover, contaminated wastewater (untreated effluent) includes both organic and inorganic matter destroys marine life, and reduces its reproductive ability. The diversity of impurities in industrial effluents has been tied to many serious health issues and damage to natural environments.

What is the industrial effluent treatment?

Industrial effluent is any wastewater that is produced by various industrial activities. The quality of industrial effluent/wastewater varies from one industry to another and is responsible for the degradation of receiving water sources. In other words, treating all kinds of effluents originating from various industries using an industrial ETP/Effluent Treatment Plant is extremely desirable.

Industrial effluent treatment is the effective process of treating wastewater that is highly contaminated by industrial wastes, making it fit for reuse or disposal/discharge back to the natural environment.

Different levels of treatment involved in Industrial Effluent Treatment Plant or ETP:

1. Preliminary Treatment or Pretreatment: Removal of large solids such as rags, ticks, grit, and grease that may damage equipment or result in operational problems. It uses bar screens and a grit chamber to remove these suspended solid materials.

2. Primary Treatment It involves the removal of floating and settleable materials such as suspended solids and organic matter. It removes about 70-80% of suspended solids and 25-30% of BOD. Sludge that settles to the bottom of the primary clarifier is pumped out and subjected to sludge processing.

3. Secondary Treatment Removal of biodegradable organic matter and suspended solids. It involves the most preferred biological aerobic process called the “activated sludge process” which effectively removes about 85% of organic matter.

4. Tertiary or Advanced Treatment It takes out residual suspended solids or dissolved solids. It improves the quality of treated water in order to comply with discharge standards. It involves a process called disinfection (which uses disinfectants like chlorine, ozone, and UV light in common) for removing any undesirable microbes.

Chemical Based Effleunt Treatment Plant

Chemical Industries produce a large amount of wastewater due to continuous washing, cleaning & manufacturing processes that go on. Our client, located at Tarapur MIDC established in the 70s is one of the prominent leaders in the manufacturing of specialty chemicals with products comprising stearates, maleates, adipates, polymeric, sebacates, benzoates, phthalates & plasticizers. Tarapur MIDC being one of the most polluted faces stern attitudes from current environmental bodies such as NGT and CPCB. The EHS department of the industry was under constant pressure to maintain varying COD, BOD, and TDS levels and control the sludge MLSS development.

This industry tried various local liquid cultures for reducing effluent parameters. However, it was incompetent at treating toxic, tough-to-degrade wastewater, which could not meet the local PCB norms.

The initial approach and challenges:

After a complete study of the plant through a questionnaire an On-site visit and a discussion EHS team, our expert understood numerous challenges to be addressed: –

Key issues

- Control over varying COD and BOD levels due to different production streams, therefore it was important to fine-tune the system and reduce outlet parameters.

- Ongoing operation of Biological systems like a batch process which provided less time for microbes to get acclimatized to incoming effluent. Here, it was important to optimize the ETP from a batch process to a continuous one without compromising the parameters.

- Foul odor generation due to inadequate treatment, which was resolved using proper plant maintenance & incorporation of optimized bacterial cultures.

Treatability Study

Before planning a treatment scheme, it was crucial to perform a treatability study to understand the wastewater characteristics and devise an appropriate treatment regime specific to their effluent. Organica’s unique wastewater treatment-based study “BioSure” is a laboratory-scale trial that confirms the suitability of the bacterial consortium present in our product and their development in the effluent. These trials were specifically designed to provide a clear indication of whether our microbes can grow in a given type of effluent without compromising the reduction of pollutants in the effluent. Microscopic analysis reports of the sample revealed satisfactory growth and development of our microbes in the effluent.

After this study, we decided to go with a treatment regime combining Cleanmaxx 202, Bioclean XLR & Microbster. There were many factors that made Organica select this set of products, some of them where

The products in the effluent:- The presence of products such as stearates, maleates, adipates, polymeric, sebacates, benzoates, and phthalate plasticizers makes it difficult for ordinary and single-strain products to sustain and perform in the effluent as they are tough to degrade hazardous compounds. Cleanmaxx 202 contains a specialized heterogenous concentrated consortium of microbes that promotes high rapid biomass generation which is important in degrading tough compounds in effluent. Howsoever, due to variations in affluence, it was important to provide extra durability to our microbes, and hence, Bioclean XLR was introduced which was specifically designed to accelerate the growth of microbes under tough conditions.

The plant design: – The plant was designed in a conventional manner of an ASP with one Aeration tank. Howsoever it was a batch process where the effluent was channelized by pumps to each section of treatment thereby giving a very lesser amount of retention time. This batch process was converted to a continuous process to maximize the plant space & give more retention time.

Elevated sludge or MLSS levels: – Microbster – our organic replacement of conventional nutrient additives was introduced to provide nutrient supply in terms of phosphorus & nitrogen to maintain the health of microbes in the system.

The Entire bioremediation program ran for 60 Days. Every parameter was closely monitored & modified when required to meet the desired results. The process was divided into 3 parts, where each one focused on a specific part of the plant.

Plant Optimization: – We recommended changes in the plant for its transition from batch to a continuous process. All the leakages & dead zones were strategically removed without the addition of any new equipment thus keeping the cost at a minimum.

Microbial Dosing: – We planned a 60-day dosing schedule. It included strategic incorporation of Cleanmaxx 202, Bioclean XLR, and Microbster. Initially, the first 4 weeks were crucial, and therefore dosing was kept high to naturally increase the population of healthy microbes and eliminate incompetent microbes. Next 4 weeks the amount decreased & the primary agenda for dosing was to maintain a constant population of microbes in the system.

Increase in Flow rate: – We kept the target of increasing the flow to 300 m3/day till the 60th Initially we started with 50 m3/day and then gradually increased the flow every week.